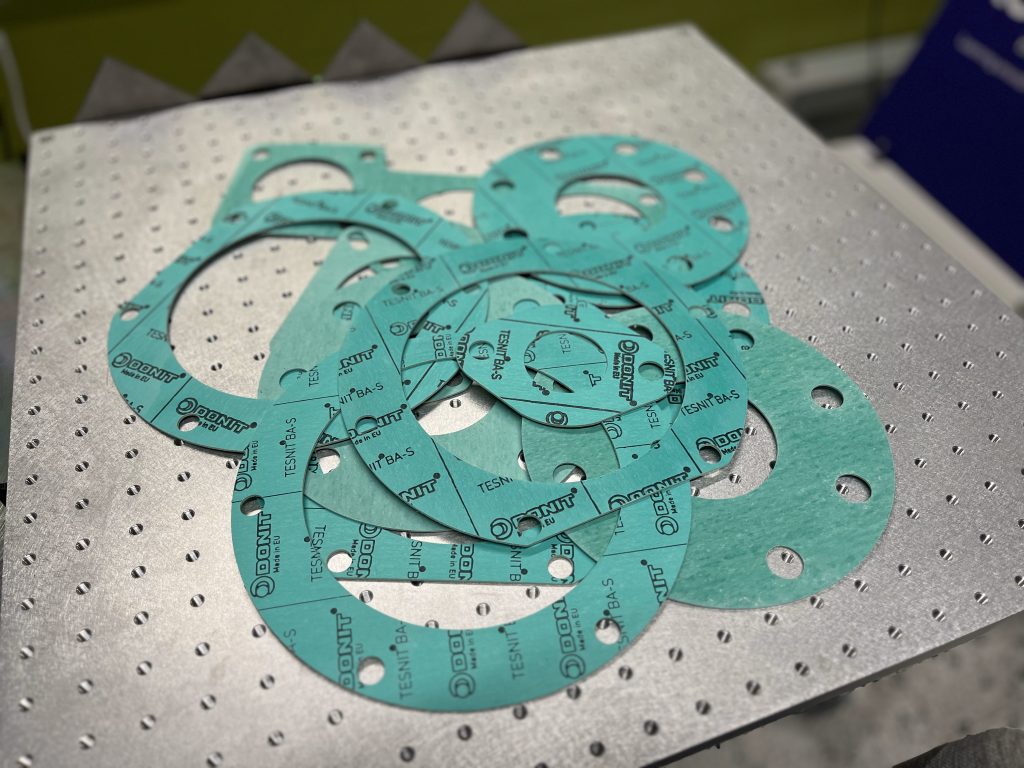

This project supports TT Gaskets in developing an automated part-handling station designed to streamline the handling of gaskets. A robot feeds gaskets into a grinding machine and then sorts the finished parts from a conveyor after processing. As part of the project, an adaptive two-finger vacuum gripper has been developed, capable of flexibly handling gaskets of various shapes. The goal of automation is to reduce reliance on manual labor in simple feeding and sorting tasks, enhancing efficiency and repeatability.

Technologies involved: Mechanics, collaborative robotics (cobotics), programming tool, simulation

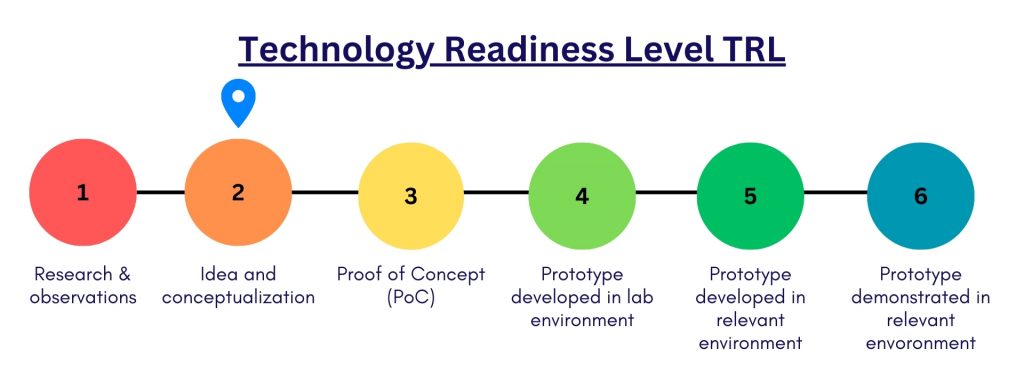

A simulation model was created based on initial designs and technical requirements. In addition, a physical prototype of the vacuum gripper was built, and the control interface between the gripper and robot was successfully demonstrated. Tampere University has provided TT Gaskets with valuable expertise in simulation, collaborative robotics, and gripper design.

TT Gaskets

TT Gaskets delivers customized sealing solutions for various industries worldwide. In addition to high-quality gaskets, the company offers services such as turnaround support, sealing training, and gasket re-manufacturing—helping clients minimize downtime and maximize performance.